- Home

- News About Us

- Go to Genba!

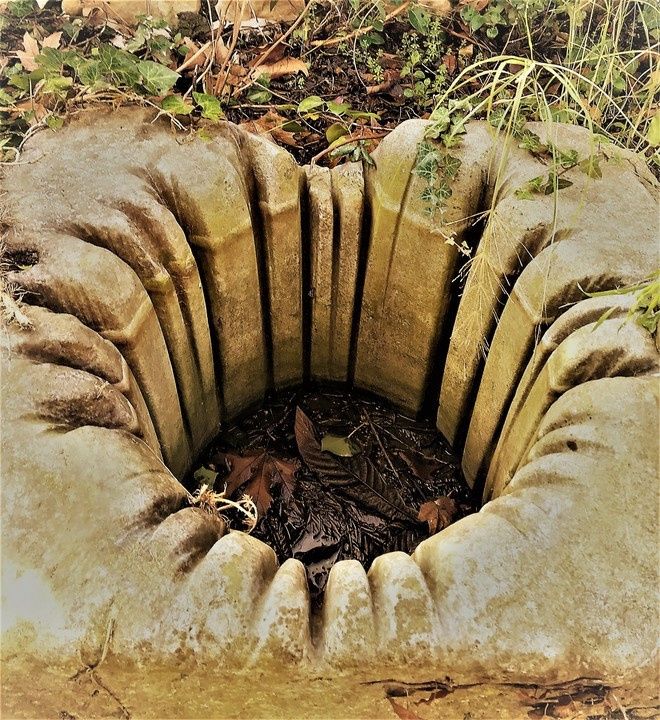

Go to Genba!

Go (literally) to the source of any issue to be able to understand it.

‘’Genba’’ is Japanese word that means the actual place where the work occurs. It might be the shop floor in a factory, it might be the shopping aisle in a super market. ‘’Going to Genba’’ means going to the source to find the facts, to see the situation with your own eyes to make better decisions. This practice is an integral part of the Japanese production philosophy. The catch is here to see what is happening yourself rather than acting on an assumption of what is happening. The objective of going to Genba is not solving the problem, it is to really understand what is going on.

Are you losing market share in a specific region, is there an increase in the cost of a certain product, aren’t you able to cooperate smoothly with a department head? Go to that region, go to that production line, go to that department and try to understand what is going on.

Try asking ‘’Where is the issue?’’ before asking ‘’What is the issue?’’ when you are faced with a problem. And start the solution identification after you have been actually there. You might find out this way you will get better solutions and results.

Here is what Taiichi Ohno, one of the master minds of the Toyota Production System says about the topic:

“Don’t look with your eyes, look with your feet. Don’t think with your head, think with your hands”. Taiichi Ohno

Going to Genba has other benefits as well. You will be creating great coaching opportunities. From the questions you are asking, your team will learn how you approach a problem. You will be leading your team to figure out what to do themselves rather than telling them what to do in a dictating way or completely missing a coaching opportunity with the easy approach of telling them ‘’don’t come to me with problems, come to me with solutions’’.

In short, the learning that I noted down in my 14th year as a corporate citizen was:

‘’Asking ‘’where’’ the issue is and going there to understand the issue is halfway in solving a problem. ‘’